.png)

포장

배송 과정 동안 와이어의 품질 유지를 보장하기 위해 포트웨인메탈에서는 광범위한 패키징 옵션을 제공합니다. 포트웨인메탈의 다양한 옵션 중에서 원하는 스풀 유형을 고객이 지정하거나, 고객의 특정 필요에 가장 잘 맞을 것으로 판단되는 스풀 유형을 포트웨인메탈이 추천해 드릴 수도 있습니다.

일부 합금은 부식되기 쉬우므로 포트웨인메탈은 와이어를 추가로 보호하기 위해 포장 백에 건조제를 추가합니다.

직선으로 펴진 와이어 및 컷 와이어는 수량에 따라 PVC 튜브 또는 나무 상자를 통해 배송됩니다.

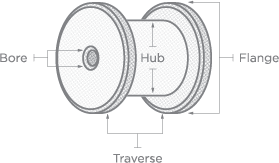

| 스풀 | 등가 | 플랜지 | 허브 | 트래버스 | 보어 | 최대 용량* | 직경 | 스풀 구성 |

|---|---|---|---|---|---|---|---|---|

|

55.88 cm x 27.94 cm |

-- |

55.88 cm |

35.56 cm |

27.94 cm |

12.7 cm |

204.1 kg |

0.762 mm - 3.66 mm |

폴리스티렌 |

|

45.72 cm x 25.4 cm |

-- |

45.72 cm |

27.94 cm |

24.38 cm |

12.7 cm |

68.03 kg |

0.762 mm - 3.66 mm |

폴리스티렌 |

|

30.48 cm x 15.24 cm |

-- |

30.48 cm |

15.24 cm |

15.24 cm |

3.3 cm |

27.21 kg |

0.304 mm - 1.524 mm |

ABS |

|

용접 와이어 |

-- |

29.72 cm |

21.08 cm |

9.2 cm |

5.08 cm |

13.60 kg |

0.102 mm - 1.27 mm |

ABS |

|

20.32 cm x 8.89 cm |

-- |

20.32 cm |

11.68 cm |

15.24 cm |

3.048 cm |

11.33 kg |

0.304 mm - 1.524 mm |

ABS |

|

15.24 cm x 8.89 cm |

-- |

15.24 cm |

8.89 cm |

8.89 cm |

1.575 cm |

4.54 kg |

0.076 mm - 0.508 mm |

ABS |

|

34.59 cm x 9.017 cm |

-- |

34.59 cm |

28.34 cm |

9.017 cm |

5.08 cm |

6.803 kg |

0.0508 mm - 0.762 mm |

ABS |

|

11.43 cm x 7.62 cm |

-- |

11.43 cm |

6.35 cm |

7.62 cm |

1.57 cm |

1.133 kg |

0.076 mm - 0.254 mm |

ABS |

|

6.35 cm x 7.62 cm |

HK 76-45 |

6.35 cm |

4.318 cm |

7.62 cm |

1.57 cm |

0.453 kg |

≤0.177 mm |

ABS |

|

HK 76-45 |

6.35 cm x 7.62 cm |

6.35 cm |

4.445 cm |

5.994 cm |

1.57 cm |

0.453 kg |

≤0.101 mm |

-- |

|

DIN80 |

-- |

8.128 cm |

5.08 cm |

6.35 cm |

1.60 cm |

0.453 kg |

≤0.0762 mm |

ABS |

|

DIN100 |

-- |

9.606 cm |

6.35 cm |

7.874 cm |

1.60 cm |

1.360 kg |

0.0254 mm - 0.127 mm |

ABS |

|

DIN125 |

HKV 125 |

12.446 cm |

7.874 cm |

9.906 cm |

1.60 cm |

2.267 kg |

0.101 mm - 0.254 mm |

ABS |

|

HKV 125 |

DIN125 |

12.496 cm |

7.112 cm |

6.502 cm |

1.60 cm |

1.360 kg |

0.101 mm - 0.254 mm |

-- |

|

DIN160 |

HKV 160 |

16.002 cm |

9.906 cm |

12.7 cm |

2.209 cm |

4.54 kg |

0.254 mm - 0.508 mm |

ABS |

|

HKV 160 |

DIN160 |

16.002 cm |

8.99 cm |

8.509 cm |

2.209 cm |

4.54 kg |

0.254 mm - 0.508 mm |

-- |

|

DIN250 |

-- |

24.892 cm |

16.002 cm |

16.002 cm |

2.209 cm |

9.071 kg |

0.304 mm - 1.016 |

ABS |

|

Wardwell 보빈 |

-- |

6.604 cm |

3.302 cm |

7.112 cm |

2.794 cm |

0.226 kg |

≤0.0762 mm |

나일론 |

|

중형 브레이더 보빈** |

-- |

4.267 cm |

2.578 cm |

2.641 cm |

1.054 cm |

0.113 kg |

≤0.0762 mm |

아세탈 공중합체 |

|

대형 브레이더 보빈** |

-- |

3.987 cm |

2.971 cm |

2.641 cm |

1.054 cm |

0.054 kg |

≤0.0762 mm |

아세탈 공중합체 |

|

새로운 England #2 |

-- |

4.318 cm |

1.574 cm |

6.35 cm |

0.762 cm |

0.340 kg |

≤0.127 mm |

나일론 |

|

Endura® 보빈** |

-- |

4.292 cm |

2.590 cm |

3.556 cm |

1.054 cm |

0.090 kg |

≤0.0762 mm |

아세탈 공중합체 |

|

* 실제 용량은 와이어 크기 및 합금 유형에 따라 달라집니다. 자세한 내용은 고객 서비스 담당자에게 확인하십시오. |

||||||||

Endura® 보빈

Endura® 보빈의 각진 플랜지 설계는 스풀링 중 와이어 밀림을 방지하고 플랜지와 와이어의 접촉을 최소화해 플랜지 토인(toe-in) 가능성을 없앱니다. 그리고 각 스풀은 걸리는 부분이 없도록 매끄러운 표면으로 꼼꼼하게 제조됩니다. 여러 Endura® 보빈은 기존의 해당 제품을 간단하게 대체할 수 있도록 설계되었기 때문에 쉽고 빠르게 바꿀 수 있습니다. 귀사의 제조 공정이 기계 가동 시간 증가로 인해 이점을 얻을 수 있는 경우 포트웨인메탈 담당자에게 Endura® 보빈이 생산성 향상에 어떠한 도움이 될 수 있는지 보여달라고 문의해 보십시오.

라벨

당사 포장 공정의 핵심은 스풀 라벨을 통한 품질 제어입니다. 스풀 라벨에 표시되는 표준 정보는 다음과 같습니다.

- 합금 유형

- 크기

- 로트 번호

- 스풀 순 중량

- 고객 구매 주문 번호

- 날짜

- 스풀 번호

- 극한 인장 강도

- 평균 절단 하중

- 와이어의 신장률

스풀 반납 및 재활용

환경에 미치는 영향을 줄이기 위한 노력으로 포트웨인메탈은 양호한 상태로 반납되는 스풀에 대해 보증금의 50%를 돌려 드리고 있습니다. (배송료는 고객 부담)

보증금의 일부를 환급 받을 자격이 되는지 확인하기 위해 다음 스펙을 충족하는 경우 스풀이 “양호한 상태”로 간주됩니다.

- 와이어 조각 또는 기타 재료 조각이 없어야 합니다.

- 새로운 구멍을 뚫는 등 변형되면 안 됩니다.

- 정상적이거나 합리적인 마모를 벗어나 손상되면 안 됩니다.

반납된 Endura® 보빈, 파손 또는 손상된 스풀과 크기 및 사용 특성으로 인해 선정된 스풀은 보증금 환급 대상이 아니지만 포트웨인메탈은 재활용을 위한 지속 가능성 프로젝트의 일환으로 이러한 보빈 및 스풀을 받습니다. 포트웨인메탈은 쓰레기 매립지로 가는 재활용 가능한 제품의 양을 줄이기 위해 제조업체 및 기타 담당 공급업체를 통해 다양한 스풀 구성을 재활용하고 있습니다.

스풀은 포트웨인메탈 재활용 센터로 바로 보내주시기 바랍니다. 그래야 시설 간 제품 배송으로 인한 환경 영향을 최소화할 수 있습니다.

Fort Wayne Metals - Building D

4030 Piper Drive

Fort Wayne, Indiana 46809

All spool returns must include a packing slip detailing the spool type, quantity, and color for all spools included in the return.

Fort Wayne Metals encourages our customers to take advantage of the spool return program. Please reach out directly to your Customer Service Assistant if you have any questions about the spool return program or recycling options. To find out more about Fort Wayne Metals Recycling Program and Sustainability Initiatives, please visit the Corporate Responsibility page.